OPENINGS FOR TECHNICAL INSTALLATIONS

Distribution without additional costs

In ceiling structures made of traditional beams, it is not possible to use the ceiling cavity to route larger installations such as sewage, ventilation, etc. It is therefore necessary to build costly suspended ceilings or installation walls.

This is not necessary with I-OSB™ wooden beams, which can be used to create cross-passages. The installation of distribution systems is therefore not only easy, but also inexpensive.

Openings for technical installations can be made in the beam in accordance with the following rules:

- only circular openings are permitted

- all openings must be located in the center of the web

- make holes in the longitudinal axis of the web

- openings with a diameter of up to 20 mm can be placed anywhere in the web, but only if the distance between the edges of the openings is at least 50 mm

- A maximum of 3 circular holes with a diameter of up to 20 mm are permitted in a single row. Do not make holes at the beam support points.

- It is not permitted to make notches in the flanges.

- It is expressly prohibited to make holes without rounded corners (without radius) and with notches.

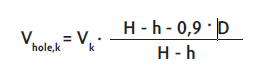

For the static design of I-OSB™ beams with circular holes, it is necessary to take into account the reduced value of the characteristic shearVhole,k, for which the following relationship applies:

where:

- Vk is the characteristic shear value according to Tables 1, 2, and 3

- H is the height of the beam

- h is the flange height of the beam

- D is the diameter of the circular hole in the web of the beam

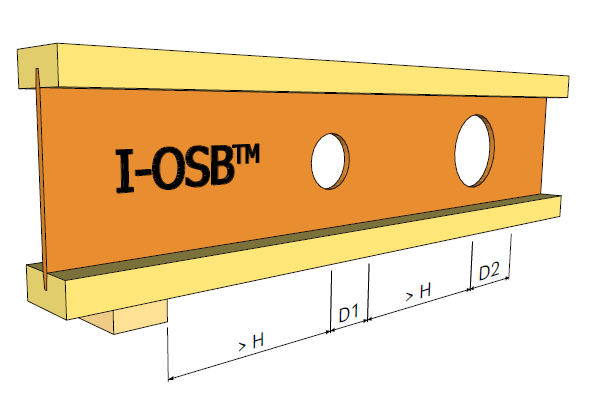

To create the hole, use the data from the following table and sketches:

| Beam height | 200 mm | 240 | 300 | 350 | 400 mm | |

|---|---|---|---|---|---|---|

| Circular holes | Minimum distance from support or concentric load F | 200 | 240 | 300 | 350 | 400 |

| Minimum distance between two holes | 200 | 240 | 300 | 350 | 400 mm | |

| Maximum diameter D | 100 | 140 | 200 mm | 200 | 200 | |