Introduction to I-beams

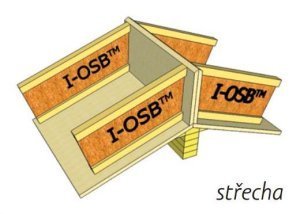

I-OSBTM beams are a new product from CZECH PAN s.r.o. They can be used as load-bearing structural elements in building structures, for example:

- building components or frames

- walls

- roofs

- ceilings.

Beams are primarily subjected to bending, shear, and concentrated loads in supports. Columns are primarily subjected to axial compressive forces, but also to transverse forces. Lightweight wood-based composite beams and columns are defined as slender and low in weight.

The system has been tested and certified by VVUD Prague. The production of I-OSBTM wooden beams is carried out in accordance with the ISO 9001:2001 quality management system and the ISO 14001:2005 environmental management system.

I-OSB7™ beams are used as load-bearing structural elements in building structures, such as building components or frames, walls, roofs, and ceilings. Beams are primarily subjected to bending, shear, and concentrated loads in supports. Columns are primarily subjected to axial compressive forces, but also to transverse forces. Lightweight wood-based composite beams and columns are defined as slender and low in weight.

I-beams are manufactured in lengths from 2 m to 13 m, with beam heights from 160 to 550 mm.

Building structures must comply with increasingly stringent standards. The requirements for thermal parameters and ecology are particularly high. The demands of architects who design large spaces with large ceiling spans are also increasing. In all these contexts, an effective solution is building elements for walls, ceilings, and roofs – I-OSB™ wooden beams. I-OSB™ wooden beams can be used in all types of buildings, including wooden buildings, or in partial constructions using classic technologies. They can also be used in the revitalization of old buildings. CZECH PAN offers beams in a wide range of standard sizes, but can also adapt production to any individual customer requirements.

Advantages of I-OSB™ beams

LIGHTWEIGHT, STABLE, AND SUITABLE FOR LARGE BUILDINGS

The flanges of I-OSB™ wooden beams are made of dried, planed softwood with finger joints. OSB boards are used for the webs, which are connected to the flanges with a wedge-glued joint. The beams are manufactured on a special line with continuous quality control, which guarantees their very high quality. Unlike traditional solid wood beams, I-OSB™ wooden beams are dimensionally stable and lighter. In addition, they are capable of carrying significant loads even in large structural dimensions such as ceilings and roofs. At the same time, the beams are very easy to handle and machine. This makes installation not only faster but also significantly cheaper.

DISTRIBUTION WITHOUT ADDITIONAL COSTS

In ceiling structures made of traditional beams, it is not possible to use the ceiling cavity to route larger installations such as sewage, ventilation, etc. It is therefore necessary to build costly suspended ceilings or installation walls. This is not necessary with I-OSB™ wooden beams, which can be used to create cross-passages. This makes installation of distribution systems easy and inexpensive.

INCREASED ENERGY EFFICIENCY AND SAFETY

In the perimeter structures of buildings – walls and roofs – increasingly better and higher quality insulation materials are being used, which improve the energy balance of finished houses. In this context, structural elements such as roof beams and wall studs also play an important role. I-OSB™ wooden beams achieve better results compared to standard beams. They also eliminate the risk of condensation forming inside the structure or on its inner surface. The perimeter structures of buildings designed with I-OSB™ wooden beams are therefore more economical and safer.